Rotomolding, that is also known as rotational molding, is actually a producing technique that requires the application of plastic material supplies to generate a wide array of products. The procedure is becoming increasingly popular since it is inexpensive, tough, and produces substantial-good quality goods. However, not lots of people are informed about it but. On this page, we shall Rotomolding check out the basic principles of rotomolding, its benefits and drawbacks, along with its applications.

1. The entire process of Rotomolding

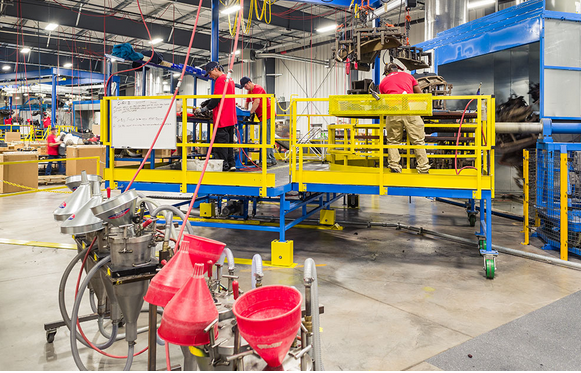

Rotomolding is actually a thermal plastic-type forming approach employed to make hollow plastic-type goods of diverse shapes and sizes. The process requires dumping plastic-type powder in to a mildew, which can be then warmed and rotated in every instructions to coat the inner surface of the mold. The mold will then be cooled, and also the concluded product is removed. The procedure can be carried out with various plastics, which include polyethylene, polypropylene, PVC, nylon material, and much more.

2. Great things about Rotomolding

One of several important features of rotomolding is that the done items are tough and very long-lasting. Rotomolding provides for the roll-out of products that are resistant against scratches, affect, and harsh climate conditions. Another advantage is that rotomolding is great for making intricate styles and fashoins that could be difficult to obtain with many other developing strategies. In addition, rotomolding is a cost-productive production approach, hence well suited for size creation.

3. Down sides of Rotomolding

Despite its quite a few benefits, rotomolding even offers its share of down sides. To begin with, the producing process is time-consuming, and generation rate is comparatively gradual, hence not well suited for producing substantial volume goods. Additionally, rotomolding needs guide participation, as well as a skilled proprietor is needed to ensure that the generation method is carried out appropriately. Ultimately, the process is just not ideal for products which require great precision and accuracy.

4. Uses of Rotomolding

Rotomolding is commonly used to produce a wide array of merchandise, such as games, play ground devices, storage space tanks, energy tanks, and more. Its capability to make complex shapes and designs causes it to be ideal for developing products which call for custom shapes, for example kayaks and canoes. Rotomolding is additionally utilized to make items that need a dual-covering for heat retaining material, such as coolers, and merchandise that need a unique colour or consistency.

5. In a nutshell

Rotomolding can be a flexible producing technique that is becoming more and more well-liked. They have positive aspects for example sturdiness, the ability to create sophisticated styles, and getting expense-successful. Nevertheless, it is not suitable for producing great quantity merchandise, as well as a qualified operator is required for your creation process. With the flexibility of rotomolding and the ability to generate unique shapes, this manufacturing technique will truly design the future of the plastic-type material industry.