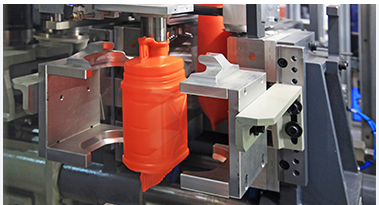

Rotomolding is actually a significantly applied industrial activity as it is quite cost-effective. Its major purpose is usually to Plastics Rotomolding design polymers, transforming them into thermoplastics. The most used polymers are PVC, polyethylene, and polypropylene in this kind of exercise.

Various companies can cause in the most basic to very sophisticated materials throughout the rotational molding method. Also, dependant upon the reason for the plastic-type substance, it is actually a more usual solution than options like coming, injection, and vacuum method.

Rotational Molding is a procedure that will allow the production of basic resources as well as a top level of difficulty. These parts are hollow and air-tight, little, just like a coin, or big, like 25,000-liter tanks.

In this type of part, the left over stresses are typically tiny because of the absence of stress about the resin. This method also handles the production of inserts, threaded elements, gussets, increase surfaces, slots, and opportunities permitting materials and colors to get easily exchanged.

A fully controlled process

To obtain superior quality pieces having a adequately-handled approach, you have to have experts. Granger Plastics Business is the best partner for companies that want the most effective plastic materials merchandise.

The various tools and molds employed in Plastics Rotomolding are much cheaper than other molding processes. This can be motivated by reduced-charge materials including nickel, aluminium, or metallic. Additionally, the pieces manufactured by them will not call for large final concluding functions.

One of the primary great things about this particular handling is that rotomolding polyethylene can lead to much stronger elements with a decent shelf-life. No matter how very much this uncooked materials is utilized by around 90% of your rotational molding market place on earth.

A completely custom made services

Not many businesses globally offer the Rotational Molding assistance offered by Granger Plastic materials Business as it provides the last concluding assistance after Molding, storage space of components, and dispatching those to finish clients.